Categories:

News

Research

Industrial Automation

Automation Components

Electric Components

Robots

Artifint

New Wave

Motors

Practical

News

Research

Industrial Automation

Automation Components

Electric Components

Robots

Artifint

New Wave

Motors

Practical

Tags:

announcement, website, testing, PLC rack, I/O, Cable, Parallel communication, Serial communication, ASCII, RS232, RS-232 Communication, ProfiBus, Industrial robots, manipulator, Cartesian robot, SCARA Robot, Articulated robot, end-of-arm-tooling, Robotics, Metalcasting, automotive industry, Integrated force sensing, shunt, electric current, Human - Machine Interface, HMI, MMI, Human Factors Engineering, Usability Engineering, User Interface, Systems Engineering, Opton, T-WIN20, T-WIN20 KDM, robot bender, pipes, PROFIBUS, Process Field Bus, communication, automation technology, PROFINET, Industrial Ethernet, Central Association for the Electrical Industry, ZVEI, PROFIBUS FMS, PROFIBUS DP, PROFIBUS International, field-bus, OSI Network model, Field bus Data Link, FDL, RS485, fiber-optic transmission, Manchester Bus Power, MBP, bus topology, Fieldbus Message Specification, Decentralized Periphery, PROFIBUS PA, PROFIdrive, PROFIsafe, The PROFIBUS User Organization, Contactor, Relay, Differences, automation, switch, power contacts, auxiliary contacts, contact springs, electromagnet, coil, armature, Grounding, shielding, EMI, Shields, PWM, RF signal, Magnetic coupling, Pulse-width-modulation, PWM simulation, EMI noise, CE mark, and many more...

Differences between Contactor and Relay

Contactor and relay are two terms often encountered when dealing with electric circuits. Both these devices are used for similar purposes and hence people are often confused about the difference between a contactor and a relay. This article clarifies the differences between the two devices to remove any confusion once and for all.

Contactor and relay are two terms often encountered when dealing with electric circuits. Both these devices are used for similar purposes and hence people are often confused about the difference between a contactor and a relay. This article clarifies the differences between the two devices to remove any confusion once and for all.Let us talk about the ignition system of your car. When you turn the ignition on, it is not the ignition that interacts directly with the battery of the car. Rather it activates an electric relay that passes the signal to start the car. The relay performs an important function here as heavy duty insulated wiring would be required to connect steering column to the battery if ignition were to be directly connected with the battery. But when a relay is used, lighter wiring can be used which not only helps in saving space but also increases safety of the vehicle.

A relay is a device that can be classified as electrically operated control switches and relays are either power relays or control relays depending upon their use. While power relays are called contactors, control relays are simply called relays.

When a relay is used to switch a large amount of electrical power through its circuits, it is given a new name, a Contactor. These contactors are very commonly used in industries for control of electric motors. Thus, it is clear that contactor is only a special type of relay.

RELAY

A relay is an electromechanical or solid-state device operated by variations in the input which, in turn, operate or control other devices connected to the output. They are used in a wide variety of applications throughout industry, such as in telephone exchanges, digital computers, motor and sequencing controls, and automation systems. Highly sophisticated relays are utilized to protect electric power systems against trouble and power blackouts as well as to regulate and control the generation and distribution of power. In the home, relays are used in refrigerators, automatic washers and dishwashers, and heat and air-conditioning controls. Although relays are generally associated with electrical circuitry, there are many other types, such as pneumatic and hydraulic. Input may be electrical and output directly mechanical, or vice-versa.

Relays are used where it is necessary to control a circuit by a low-power signal (with complete electrical isolation between control and controlled circuits), or where several circuits must be controlled by one signal. Solid-state relays control power circuits with no moving parts, instead using a semiconductor device to perform switching.

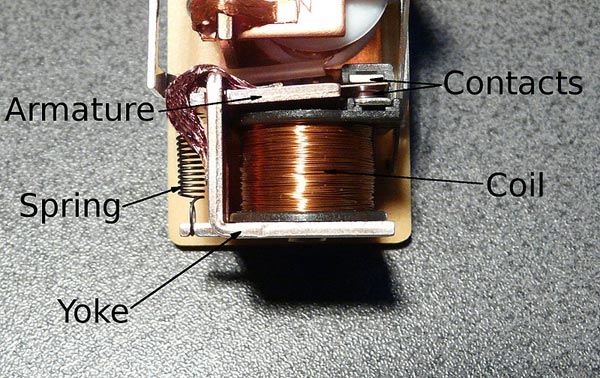

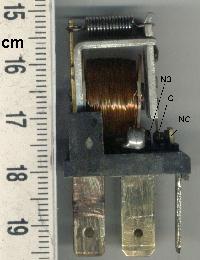

A simple electromagnetic relay consists of a coil of wire wrapped around a soft iron core, an iron yoke which provides a low reluctance path for magnetic flux, a movable iron armature, and one or more sets of contacts. The armature is hinged to the yoke and mechanically linked to one or more sets of moving contacts. It is held in place by a spring so that when the relay is de-energized there is an air gap in the magnetic circuit.

When an electric current is passed through the coil it generates a magnetic field that activates the armature, and the consequent movement of the movable contact(s) either makes or breaks (depending upon construction) a connection with a fixed contact. If the set of contacts was closed when the relay was de-energized, then the movement opens the contacts and breaks the connection, and vice versa if the contacts were open. When the current to the coil is switched off, the armature is returned by a force, approximately half as strong as the magnetic force, to its relaxed position. Usually this force is provided by a spring, but gravity is also used commonly in industrial motor starters. Most relays are manufactured to operate quickly. In a low-voltage application this reduces noise; in a high voltage or current application it reduces arcing.

When the coil is energized with direct current, a diode is often placed across the coil to dissipate the energy from the collapsing magnetic field at deactivation, which would otherwise generate a voltage spike dangerous to semiconductor circuit components. Some automotive relays include a diode inside the relay case. Alternatively, a contact protection network consisting of a capacitor and resistor in series (snubber circuit) may absorb the surge. If the coil is designed to be energized with alternating current (AC), a small copper "shading ring" can be crimped to the end of the solenoid, creating a small out-of-phase current which increases the minimum pull on the armature during the AC cycle.

CONTACTOR

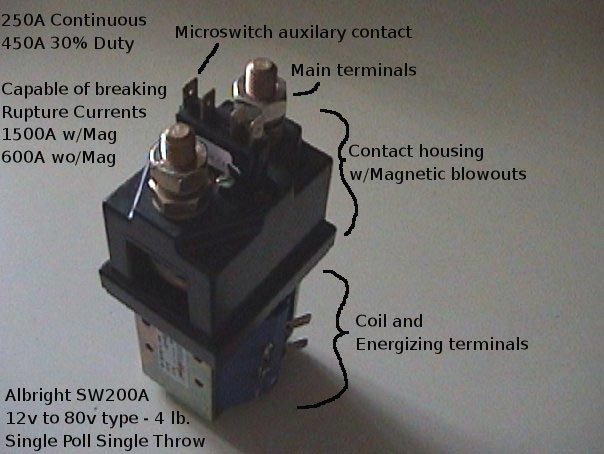

A contactor is an electrically controlled switch used for switching a power circuit, similar to a relay except with higher current ratings. A contactor is controlled by a circuit which has a much lower power level than the switched circuit. Contactors come in many forms with varying capacities and features. Unlike a circuit breaker, a contactor is not intended to interrupt a short circuit current. Contactors range from those having a breaking current of several amperes to thousands of amperes and 24 V DC to many kilovolts. The physical size of contactors ranges from a device small enough to pick up with one hand, to large devices approximately a meter (yard) on a side. Contactors are used to control electric motors, lighting, heating, capacitor banks, and other electrical loads.

A contactor has three components. The contacts are the current carrying part of the contactor. This includes power contacts, auxiliary contacts, and contact springs. The electromagnet (or "coil") provides the driving force to close the contacts. The enclosure is a frame housing the contact and the electromagnet.

A basic contactor will have a coil input (which may be driven by either an AC or DC supply depending on the contactor design). The coil may be energized at the same voltage as the motor, or may be separately controlled with a lower coil voltage better suited to control by programmable controllers and lower-voltage pilot devices.

Unlike general-purpose relays, contactors are designed to be directly connected to high-current load devices. Relays tend to be of lower capacity and are usually designed for both normally closed and normally open applications. Devices switching more than 15 amperes or in circuits rated more than a few kilowatts are usually called contactors. Apart from optional auxiliary low current contacts, contactors are almost exclusively fitted with normally open contacts. Unlike relays, contactors are designed with features to control and suppress the arc produced when interrupting heavy motor currents.

When current passes through the electromagnet, a magnetic field is produced, which attracts the moving core of the contactor. The electromagnet coil draws more current initially, until its inductance increases when the metal core enters the coil. The moving contact is propelled by the moving core; the force developed by the electromagnet holds the moving and fixed contacts together. When the contactor coil is de-energized, gravity or a spring returns the electromagnet core to its initial position and opens the contacts.

Differences between Contactor and Relay:

- Since a contactor is required for a higher load, a relay is always cheaper than a contactor.

- A relay is normally used in appliances below 5KW, while a contactor is preferred when the appliance is heavier.

- A relay is used only in control circuit while a contactor can be used in both control and power circuits.

- In general contactors are little slower than relays

- Contactor is so designed that it can be repaired while it is not normally done in the case of relays.

This post belongs to category: